|

You will be working in the Woodworking Room . In order to keep safe from hazards created by you or other workers using any of the tools in this room, the following precautions apply in addition to any other precautions:

Safety

Hazards

- Dust

- Noise

- Fire (friction from tools, polymerizing oils)

- Projectile (materials or tools shattering, kicking back)

- Laceration (sharp tools or workpieces)

- Entanglement (spinning parts sucking user into equipment)

PPE

- Hearing Protection

- Respiratory protection (minimum N95 mask; respirator preferred)

- Safety Glasses

- Safety shoes

Tie back or remove loose hair, clothing, jewelry, etc.

Precautions

Do

- Read the Safe Work Procedure and obtain North Forge approval before using the equipment for the first time.

- Plan cuts carefully; use safety devices (push sticks, clamps, sleds, featherboards) where required.

- Maintain a calm but vigilant attitude. If you are stressed or in a hurry, it’s best not to use the equipment.

- Tie back long hair and jewelry; remove earbuds and hoodie cords.

- Check the workspace for slip and trip hazards.

- Ensure the equipment is in good condition (guards installed and working, blades are sharp and intact, no clogs in dust extraction hoses).

- Make sure others in the area are aware of what you're doing. Warn any bystanders if your work can affect them.

- Inspect the material for cracks, knots, or debris before starting - material can shatter or kick back if it is not stable.

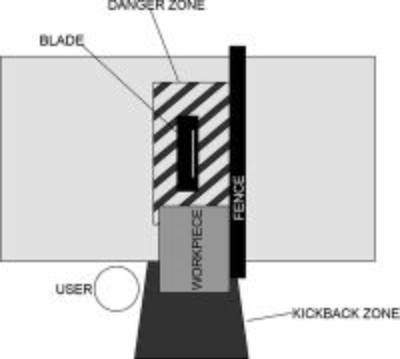

- Stand outside of any kickback zones.

- Check the equipment for trapped debris when done, particularly trapped beside or under blades.

- Use a brush and/or vacuum to clean most of the dust before finishing with compressed air.

- Follow instructions in Oily Rags Bins

Do not

- Use the equipment if you are tired, intoxicated, or otherwise impaired

- Rush

- Distract operators - if you need to get someone’s attention, stand to the side and wait until they notice you. Do not wave, shout, or touch the operator.

- Leave the equipment with equipment still running - note that hearing protection can prevent users from hearing when the blade is/is not running.

- Cut or sand metal due to risk of sparks and equipment/property damage.

- Dispose of oily rags in the general waste bins.

Housekeeping

- Check the working area for slip and trip hazards (sawdust, oil, offcuts) before and after working

- Do not leave air hoses or extension cords laying across walkways where people can trip on them

- Check hoses for excess sawdust or other clogs

- Empty the dust collector if it is filled to more than halfway up the viewing window (~1 garbage bag worth of dust)

- Empty waste bins if they are more than 75% full

- Bag waste should be less than 6x6”

- Blunt any sharp corners that could puncture the bag

- Replace waste bags after emptying

- Firewood bins are only for untreated wood with no paints or stains

- Spread oily rags out to dry and dispose of them in the oily rags bin.

- Return all fab lab tools to their proper locations

- Remove all personal tools, materials, and equipment from the room

- Fire code prohibits storing material in the wood room

- Turn off the equipment and dust collector.

- Turn off the room exhaust if you are the last one in the room.

- Room exhaust is interlocked with equipment power; turning off the exhaust will turn off all equipment in the room!

|