More actions

John Hache (talk | contribs) Added photos with bad formatting |

John Hache (talk | contribs) Photos reformatting, add some instruction text, will finish later. |

||

| Line 139: | Line 139: | ||

== Photo Dump (temp) == | == Photo Dump (temp) == | ||

[[File:Nf20wrench.jpg|thumb|Tighten the collet nut]] | |||

[[File:Nf19colletfix.jpg|thumb|Load the collet into the fixture]] | |||

[[File:Nf16colletbuild.jpg|thumb|Load the collet into the nut]] | |||

[[File:Nf15colletclean.jpg|thumb|Clean the tool holder with compressed air]] | [[File:Nf15colletclean.jpg|thumb|Clean the tool holder with compressed air]] | ||

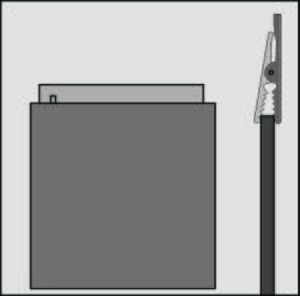

[[File:Nf24zclip.jpg|thumb|Z-axis zero clip]] | [[File:Nf24zclip.jpg|thumb|Z-axis zero clip]] | ||

[[File:Nf27storez.jpg|thumb|Z zero plate storage]] | [[File:Nf27storez.jpg|thumb|Z zero plate storage]] | ||

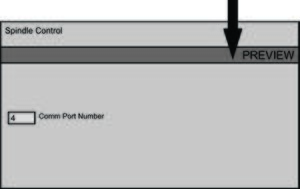

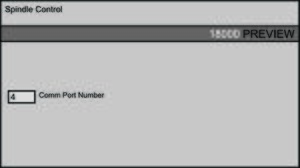

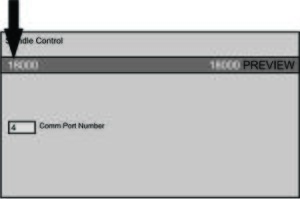

[[File:Nf29enterRPM1.jpg|thumb|Entering RPM (1)]] | [[File:Nf29enterRPM1.jpg|thumb|Entering RPM (1)]] | ||

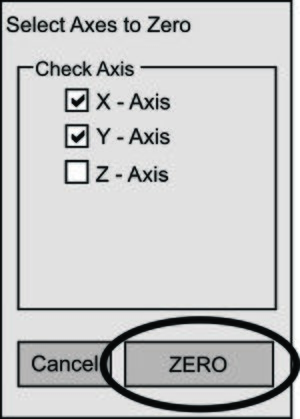

[[File:Nf23xyzero.jpg|thumb|XY Zero]] | [[File:Nf23xyzero.jpg|thumb|XY Zero]] | ||

[[File:Nf25testconnect.jpg|thumb|Test Connection]] | [[File:Nf25testconnect.jpg|thumb|Test Connection]] | ||

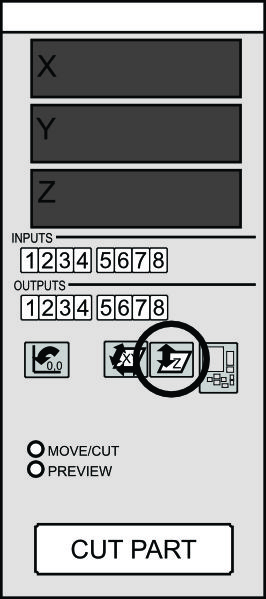

[[File:Nf26zroutine.jpg|thumb|Z zero routine]] | [[File:Nf26zroutine.jpg|thumb|Z zero routine]] | ||

[[File:Nf28RPMcheck.jpg|thumb|Spindle RPM check]] | [[File:Nf28RPMcheck.jpg|thumb|Spindle RPM check]] | ||

[[File:Nf30enterRPM2.jpg|thumb|Enter RPM (2)]] | [[File:Nf30enterRPM2.jpg|thumb|Enter RPM (2)]] | ||

[[File:Nf31enterRPM3.jpg|thumb|Enter RPM (3)]] | [[File:Nf31enterRPM3.jpg|thumb|Enter RPM (3)]] | ||

[[File:Nf32dustcheck.jpg|thumb|Check dust collector]] | [[File:Nf32dustcheck.jpg|thumb|Check dust collector]] | ||

[[File:Nf33filetransfer.jpg|thumb|Transfer files, otherwise the ShopBot won't be able to read them]] | [[File:Nf33filetransfer.jpg|thumb|Transfer files, otherwise the ShopBot won't be able to read them]] | ||

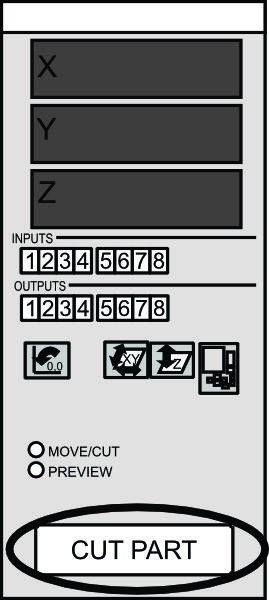

[[File:Nf34cutpart.jpg|thumb|Select Cut Part]] | [[File:Nf34cutpart.jpg|thumb|Select Cut Part]] | ||

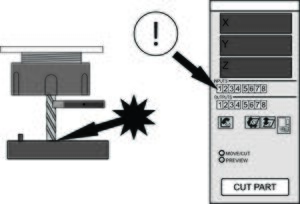

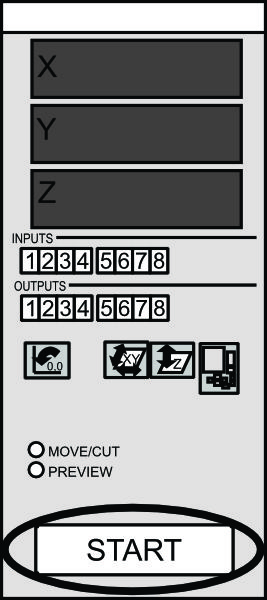

[[File:Nf35startpress.jpg|thumb|Press Start on-screen (ignore the information screen that pops up)]] | [[File:Nf35startpress.jpg|thumb|Press Start on-screen (ignore the information screen that pops up)]] | ||

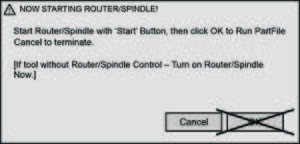

[[File:Nf36startwarn.jpg|thumb|WARNING: Turn on spindle and dust collector before pressing OK!]] | [[File:Nf36startwarn.jpg|thumb|WARNING: Turn on spindle and dust collector before pressing OK!]] | ||

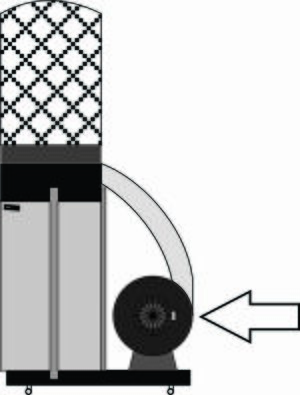

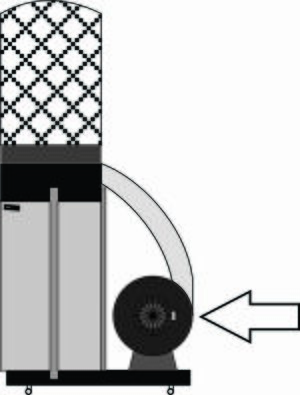

[[File:Nf37duston40dustoff.jpg|thumb|Turn the dust collector on]] | [[File:Nf37duston40dustoff.jpg|thumb|Turn the dust collector on]] | ||

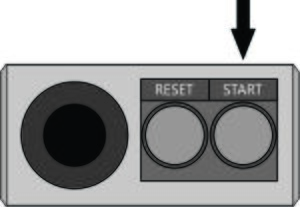

[[File:Nf38spindlestart.jpg|thumb|Press the spindle start button]] | [[File:Nf38spindlestart.jpg|thumb|Press the spindle start button]] | ||

[[File:Nf39jobrun.jpg|thumb|Press OK; the job will start.[[File:Nf37duston40dustoff.jpg|thumb|Turn off the dust collector]] | |||

[[File:Nf41vacuumoff.jpg|thumb|Open bypass valve, wait, then turn off the vacuum.[[File:Nf21loadup.jpg|thumb|Remove the tool]][[File:Nf9arrow.jpg|thumb|Move the head to the front of the bed[[File:Nf43restblock.jpg|thumb|Install the rest block[[File:Nf46poweroff.jpg|thumb|Turn off the power[[File:Nf47airoff.jpg|thumb|Turn off the air[[File:Nf49exhaustoff.jpg|thumb|Turn off the room exhaust (if you are the last one in the room) | [[File:Nf39jobrun.jpg|thumb|Press OK; the job will start.]] | ||

[[File:Nf37duston40dustoff.jpg|thumb|Turn off the dust collector]] | |||

[[File:Nf41vacuumoff.jpg|thumb|Open bypass valve, wait, then turn off the vacuum.]] | |||

[[File:Nf21loadup.jpg|thumb|Remove the tool]] | |||

[[File:Nf9arrow.jpg|thumb|Move the head to the front of the bed]] | |||

[[File:Nf43restblock.jpg|thumb|Install the rest block]] | |||

[[File:Nf46poweroff.jpg|thumb|Turn off the power]] | |||

[[File:Nf47airoff.jpg|thumb|Turn off the air]] | |||

[[File:Nf49exhaustoff.jpg|thumb|Turn off the room exhaust (if you are the last one in the room)]] | |||

== Operations == | == Operations == | ||

| Line 179: | Line 212: | ||

<div style="clear: both"></div> | <div style="clear: both"></div> | ||

=== Setup === | === Setup === | ||

1. Turn on the room exhaust | 1. Turn on the room exhaust. | ||

[[File:Nf1RoomExhaust.jpg|thumb|200x200px|left|Room Exhaust]] | [[File:Nf1RoomExhaust.jpg|thumb|200x200px|left|Room Exhaust]] | ||

<div style="clear: both"></div> | <div style="clear: both"></div> | ||

2. | |||

2. Turn on the computer. | |||

[[File:Nf2computeron.jpg|thumb|200x200px|left|Computer on]] | |||

<div style="clear: both"></div> | |||

3. Turn on the air. | |||

[[File:Nf3airon.jpg|thumb|200x200px|left|Air on]] | |||

<div style="clear: both"></div> | |||

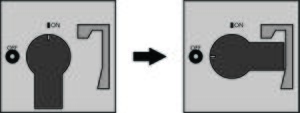

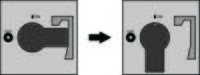

4. Reset the E-STOP. | |||

[[File:Nf4estop.jpg|thumb|200x200px|left|Reset E-Stop]] | |||

<div style="clear: both"></div> | |||

5. Turn on the ShopBot power (right side of machine). | |||

[[File:Nf5poweron.jpg|200x200px|thumb|left|Turn on the power]] | |||

<div style="clear: both"></div> | |||

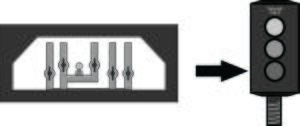

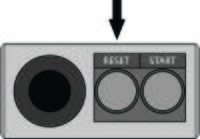

6. Press RESET on the remote. | |||

[[File:Nf6reset.jpg|thumb|200x200px|left|Press RESET]] | |||

<div style="clear: both"></div> | |||

7. Start ShopBot 3 Software | |||

[[File:Nf7shopbotswr.jpg|thumb|200x200px|left|Start ShopBot software]] | |||

<div style="clear: both"></div> | |||

8. Open the Key Pad | |||

[[File:Nf8keypad.jpg|thumb|200x200px|left|Open KeyPad]] | |||

<div style="clear: both"></div> | |||

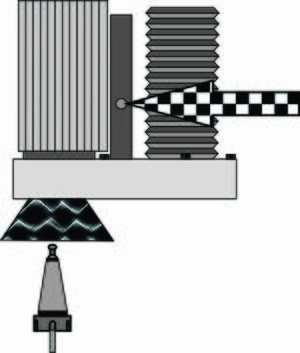

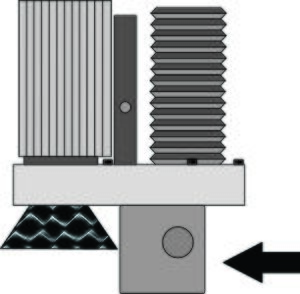

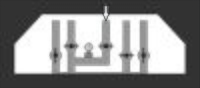

9. Use the arrow keys to move the head around | |||

*On the keyboard: use the arrow keys for XY movement, Page UP/Page DOWN to move Z axis | |||

*On screen: use the arrow buttons to manually move the head, or type the destination location and use GOTO | |||

[[File:Nf9arrow.jpg|thumb|200x200px|left|Use arrow keys to move]] | |||

<div style="clear: both"></div> | |||

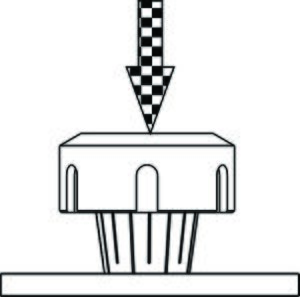

10. Load the spoilboard and/or material. | |||

11. Start the vacuum table per vacuum table instructions. | |||

=== Vacuum Table === | === Vacuum Table === | ||

1. Clean the table of debris (wear respiratory protection if using compressed air). Debris can affect part accuracy. | |||

[[File:Nf11cleanload48cleanup.jpg|thumb|200x200px|left|Clean the table]] | |||

<div style="clear: both"></div> | |||

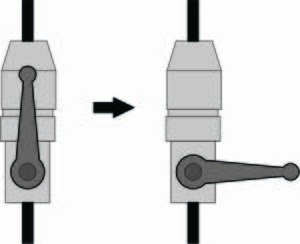

2. Open all valves on the vacuum table (OPEN = valve handle parallel to pipe) | |||

[[File:Nf10vacuum12valveopen.jpg|thumb|200x200px|left|Vacuum table]] | |||

<div style="clear: both"></div> | |||

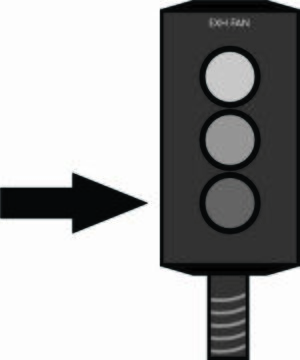

3. Turn on the vacuum table using the remote outside the room. | |||

[[File:Nf13vacuumon.jpg|thumb|200x200px|left|Vacuum remote]] | |||

<div style="clear: both"></div> | |||

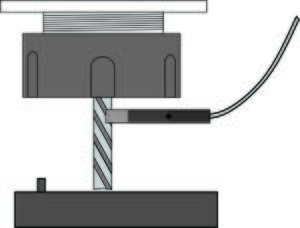

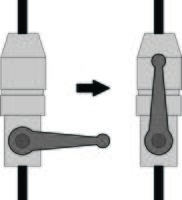

4. Close the BYPASS valve (middle) and any unused zones. | |||

[[File:Nf14bypass.jpg|thumb|200x200px|left|Byass valve]] | |||

<div style="clear: both"></div> | |||

5. Check the hold by pressing horizontally on the spoilboard. | |||

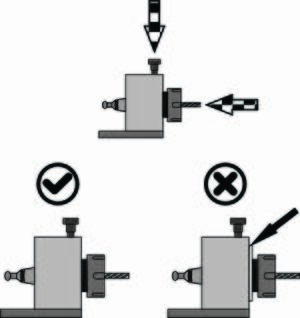

=== Tool Holder === | === Tool Holder === | ||

Revision as of 15:25, 2024 June 29

Want to learn about Aspire? See Instructions:Aspire

Safety

Fire Notice

DANGER: FIRE. The ShopBot vacuum and dust extractor make it difficult to notice a fire until it has already started spreading. Always carefully plan cuts and monitor jobs closely.

If you notice any of the following:

- Burning smell

- Charring

- Tool damage

- Unusual Vibration

- Change in sound

STOP AND INSPECT THE DUST COLLECTOR FOR SIGNS OF FIRE. More details to follow here.

PPE

Wear:

- Safety Glasses (to protect against flying dust and debris).

- Hearing protection (to protect against noise greater than 85 dBa).

- Respiratory Protection (N95 dust mask or respirator) to protect against airborne dust when cleaning or running the equipment.

Hazards

| Hazard | Causes | Mitigation | |

|---|---|---|---|

| Fire | Friction from tools, improperly installed tools | Use correct feeds and speeds

Make sure the tool sticks out far enough Do not leave the ShopBot unattended |

|

| Projectiles | Workpiece shattering

Tool shattering Tool slipping Collision with fixtures and clamps Debris in wood |

Check for cracks, knots, and debris in wood

Clean tool holder with compressed air Program file to avoid collisions Check that actual home position matches programmed home position |

|

| Entanglement | Pinch points

Rapidly moving automatic equipment |

No loose hair, clothing, earbuds, hoodie strings, etc

|

|

| Noise | Motor noise, vacuum noise, tooling noise | Wear hearing protection | |

| Inhalation | Airborne dust | Wear dust mask or respirator (minimum N95) while operating and cleaning |

Most issues are caused by:

- Improper feeds and speeds

- Improper tooling

- Improper fixturing

- Improper programming/setup (offset mistakenly applied, not setting zeroes consistent with the programming, not avoiding fixtures)

Housekeeping

Empty the dust collector when the dust has piled halfway up the viewing window.

Break down large pieces before putting them garbage bins. Blunt sharp corners to avoid puncturing the bag and injuring the person carrying it.

After use, clean the equipment and surrounding area:

- While wearing respiratory protection, use compressed air to clean the gantry. Focus on areas where parts interact: rack and pinion, spindle mount, motor mounts, etc.

- Clean the floor using a broom and dustpan, shop vacuum, or the dust collector hose. Replace the dust collector hose when done.

- Empty any garbage bins that are more than 75% full and replace the bag.

- Empty the dust collector if required.

- Return fab lab tools to their proper locations:

- Tool holders on the rack

- Collets in the drawer

- Collet wrench placed beside locking fixture

- Calipers, drills/impact drivers, squares, hand tools in the tool room

- Remove any personal tools, materials, and removable media from the room. The workbench should only have the wrench and locking fixture on it when done. Due to local fire code, do not store stock materials in the CNC room (fixtures are OK - label with name and phone number)

- Turn off the equipment per shutdown procedures.

- Turn off the dust collector. If you are the last one in the room, turn off the room exhaust. The room exhaust is interlocked to the electrical system; turning off the room exhaust will turn off all equipment in the room.

Workholding Policies

Most profile cuts will cut entirely through the workpiece and into the spoilboard below. In order to cut all the way through the material without unnecessarily damaging the spoilboard, North Forge suggests programming cuts using the following formula:

Depth of Cut = Stock Thickness + 0.01”

Always measure stock thickness with calipers, never with tape measures or nominal dimensions.

If your cut penetrates deeper than 0.06” into the spoilboard, please stop and investigate. If the stock is set up correctly and the depth of cut is appropriate, the collet may be dirty or damaged and the tool slipping out, or the secondary spoilboard may not be perfectly parallel to the gantry (for example due to debris between the primary and secondary spoilboard).

SCREWS

When using North Forge’s secondary spoilboard, it is okay to screw the workpiece in place. Do not screw into the main vacuum spoilboard. Do not use excessively long screws (ie long enough to pierce both the secondary spoilboard and the vacuum spoilboard).

SPRAY ADHESIVE METHOD

It is also possible to use spray adhesive to secure the entire workpiece to the secondary spoilboard.

- Cover both the bottom of the workpiece and the appropriate part of the spoilboard with masking tape or painter’s tape.

- Spray both surfaces with spray adhesive.

- Press the two surfaces firmly together and hold for 30 seconds.

- Test the hold by trying to move the workpiece sideways.

Other

Other workholding arrangements are possible, including vices, pins, clamps, custom fixtures, and the vacuum system.

If you are cutting all the way through a large workpiece on the vacuum spoilboard, BE CAREFUL. There is a high risk of damaging the vacuum spoilboard. It’s a good idea to test cut settings on a small workpiece and a secondary spoilboard.

The primary goal of workholding is to control the movement of the workpiece in three axes: X, Y, and Z. Always carefully check toolpaths to ensure they will not collide with any fixturing.

TIP: After a cut operation, the ShopBot will move to the “Z Safe height” before moving rapidly to its next position. When using clamps or other fixturing, adjust the Z Safe Height in the CAM software such that the Z safe height is above the clamp or fixture.

Photo Dump (temp)

Operations

Instructions and proper formatting will follow.

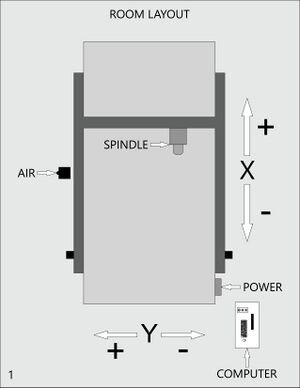

Room Layout

Pay attention to the axis system when programming. Maybe some text will fix the formatting.

Vacuum Zones

The vacuum table has four zones. Open the valves for the zones that you are using. Close the valves for the zones that you are not using.

Setup

1. Turn on the room exhaust.

2. Turn on the computer.

3. Turn on the air.

4. Reset the E-STOP.

5. Turn on the ShopBot power (right side of machine).

6. Press RESET on the remote.

7. Start ShopBot 3 Software

8. Open the Key Pad

9. Use the arrow keys to move the head around

- On the keyboard: use the arrow keys for XY movement, Page UP/Page DOWN to move Z axis

- On screen: use the arrow buttons to manually move the head, or type the destination location and use GOTO

10. Load the spoilboard and/or material.

11. Start the vacuum table per vacuum table instructions.

Vacuum Table

1. Clean the table of debris (wear respiratory protection if using compressed air). Debris can affect part accuracy.

2. Open all valves on the vacuum table (OPEN = valve handle parallel to pipe)

3. Turn on the vacuum table using the remote outside the room.

4. Close the BYPASS valve (middle) and any unused zones.

5. Check the hold by pressing horizontally on the spoilboard.